-40%

Rosler Wire Belt Blast Cleaning Machine - Model JMB24x10/4

$ 81840

- Description

- Size Guide

Description

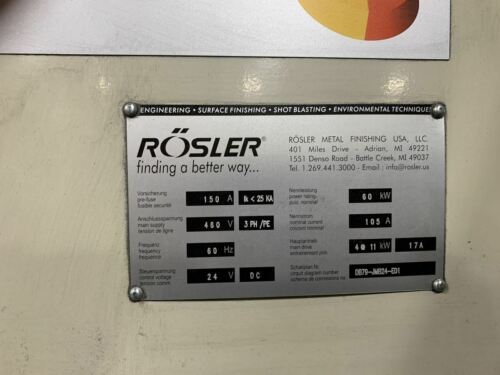

Rosler Wire Belt Blast Cleaning MachineModel #:

JMB24x10/4

Serial #:

DB000079

MFG YR:

2010

Condition:

Used; In excellent condition

Notes:

This unit was used up until May 2021 within a

Japanese

Automotive Parts Manufacturer. They are changing the process at this plant and no longer need it.

SPECIFICATIONS

Belt Height From Floor:

43"

Belt Width:

24"

Wire Diameter:

0.25"

Wire Mesh Opening:

1.12" x 1.12"

Blast Wheel Power:

15 HP

Blast Wheel Dia.:

12"

Blast Wheel Rotation Speed:

3,600 RPM

Abrasive Velocity:

240 ft/sec

Abrasive Flow Rate:

400 lbs/min

Blade Width:

3.5"

Equipped With:

Programmable Logic Control

(4) Blast Wheels (2 Attached to Machine, 2 Palleted)

40" W Air Wash Seperator

25.5" Continuous Mesh Belt

Abrasive Recovery and Cleaning System

2500 CFM Rosler RF2-4 Dust Collector

Machine Description

The JMB 24x10/4 Wire Mesh Belt Blast Machine is designed to clean soot, burned oil, and to

de-burr parts. This machine is completed by four 15 HP direct drive blast wheels. The parts are

loaded (by customer) onto a 25.5" wide continuous manganese wire mesh belt, which

transports them through the blast machine and into the unload area.

Wheel

Assembly

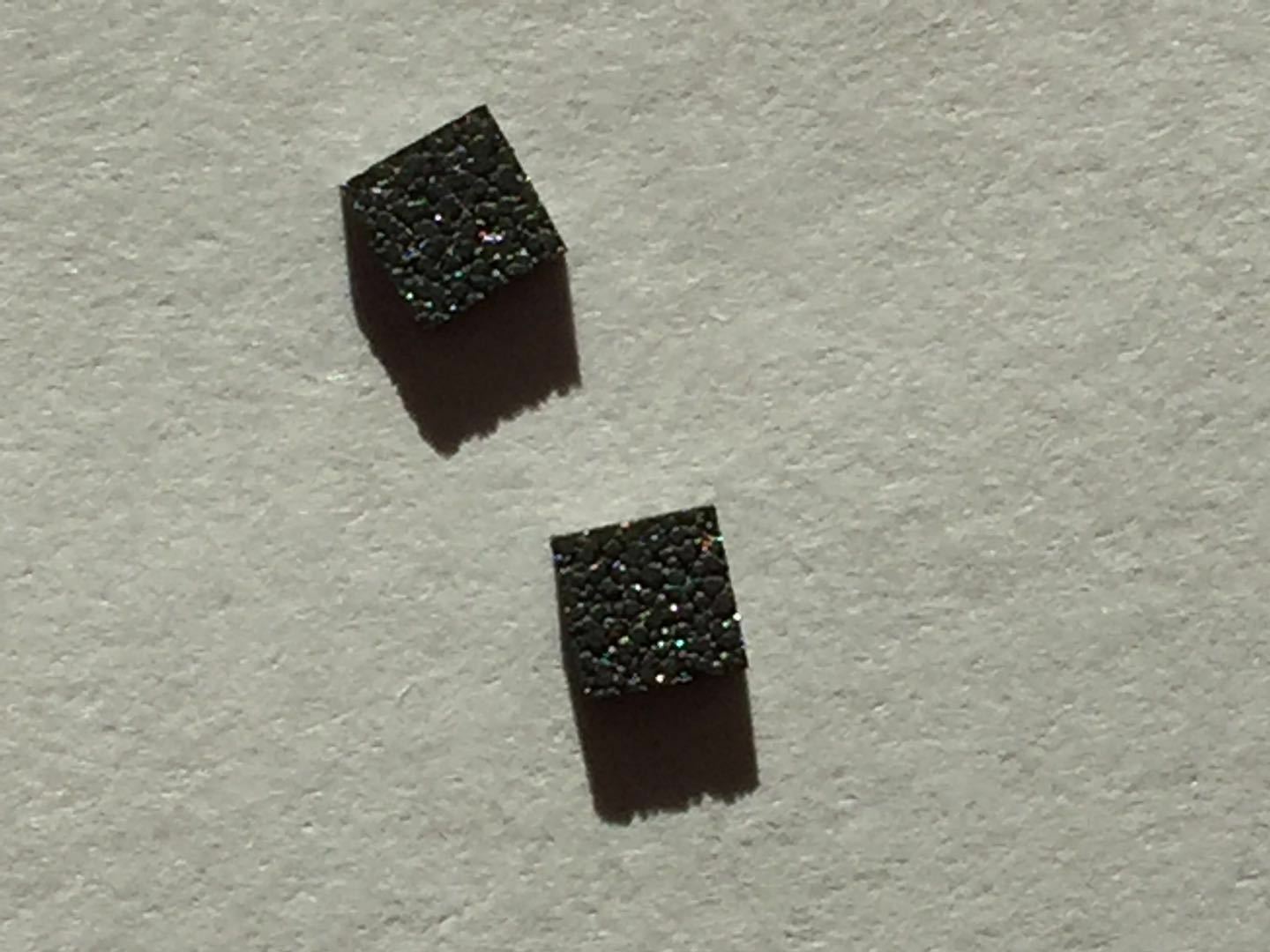

Clean blasting media is supplied to the blast wheel through the feed spout. The impeller rotates

to feed small quantities of blast media to the opening in the fixed control cage, and onto the

rotating blades. The blades fling the media onto the components being treated.

All blast wheel machines, irrespective of type, require the blast wheel to be correctly set in

order to achieve optimum treatment of the part. incorrectly set blast wheels will lead to

increased wear of the lining, and the internal blasting chamber.

The JMB 24x10/4 is equipped with four 15 horsepower direct drive blast wheels. Two blast

wheels are located on top of the blast cabinet to blast downwards to clean the top of the parts,

and two are mounted on the bottom of the blast cabinet to blast upwards to clean the bottom

side of the parts.

For Additional Information including Spec and Prints please message us.

Listing and template services provided by inkFrog